7X Line BIG and flexible

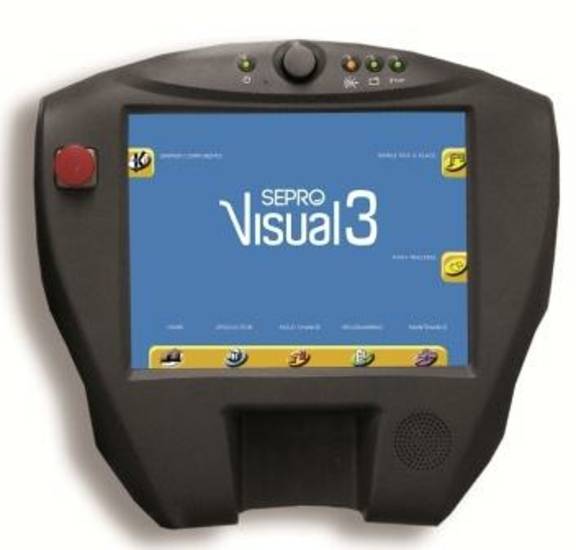

The 7X Line of 5-axis robots offers the ideal combination of Sepro new generation high-capacity 3-axis linear robots and Stäubli 2-axis digital rotation. These are precise, flexible robots capable of extracting and loading technically complex parts into the mold or IMM peripherals. Visual 3 control system

Download the brochurePresentation

- Designed for an increased structural rigidity.

- Linear rails designed for greater speed.

- Powerful servomotors and intelligent anti-vibration software.

- Path tracking function standard with Visual 3.

- Telescopic or compact telescopic vertical arm for maximum flexibility.

- Heavy load option available on all 3 sizes, up to 100kgs.

- Y free function.

Control systems

Specifications

Applications

- Complex universal unloading applications for ejected parts

- Post processing of parts

- Simple Pick & Place

- Simple stacking applications

- Complex applications: stacking, advanced palletizing, insert placing, insert molding, vision

- Path tracking

- Applications requiring multiple part orientations in space

- Network communication with peripherals

You may also be interested in:

Technology Multi Inject

Premium 6X Visual: Sepro - Yaskawa

Contact our sales team

All fields are required

How can we help you?

The information collected by SEPRO ROBOTIQUE is processed electronically in order to set up commercial relations between you and SEPRO ROBOTIQUE's Sales Department. Data points collected via this form are required except those marked as optional. Data recipient is SEPRO ROBOTIQUE's Sales Department, the data controller. Your data will be kept for the time necessary to process your requests. Pursuant to the French Data Protection Act of 6 January 1978, as amended, and the GDPR, you have the right to access, query, limit, transfer, modify, correct, and erase your personal data. You may also object at any time to the processing of your personal data. You can exercise these rights by sending us an e-mail to the following address: dataprotection@sepro-group.com or by writing to SEPRO ROBOTIQUE SAS, Henry Bessemer Street, ZI Acti-Est, CS 10084, 85003 La Roche Sur Yon, and including a copy of their signed identity document.