Programming and optimising production cycles

下期

On request

37 Waterside Barns, Lodge Farm Centre, Castlethorpe Business, Milton Keynes MK19 7ES

Be able to analyse and program simple applications (part grip and release). Be able to optimise a program.

Hardware Safety Procedures for starting production Production: start - stop

The Simple Pick & Place module Creating cycles with Simple Pick & Place The cycle parameters

The cycle parameters

Program structure Basic instructions Writing and testing a simple program with cycle parameters IMM / Robot interface Creating and testing a program with interface

Extended programming of the numeric axes and cycle options Numeric control system’s capacities Creating and testing an optimised program Memory management Creating EPS sources The condition test Studying the functions: . Programming on the PC . Simple palletising . The cycle counters Studying real applications

周期

编程

控制系统

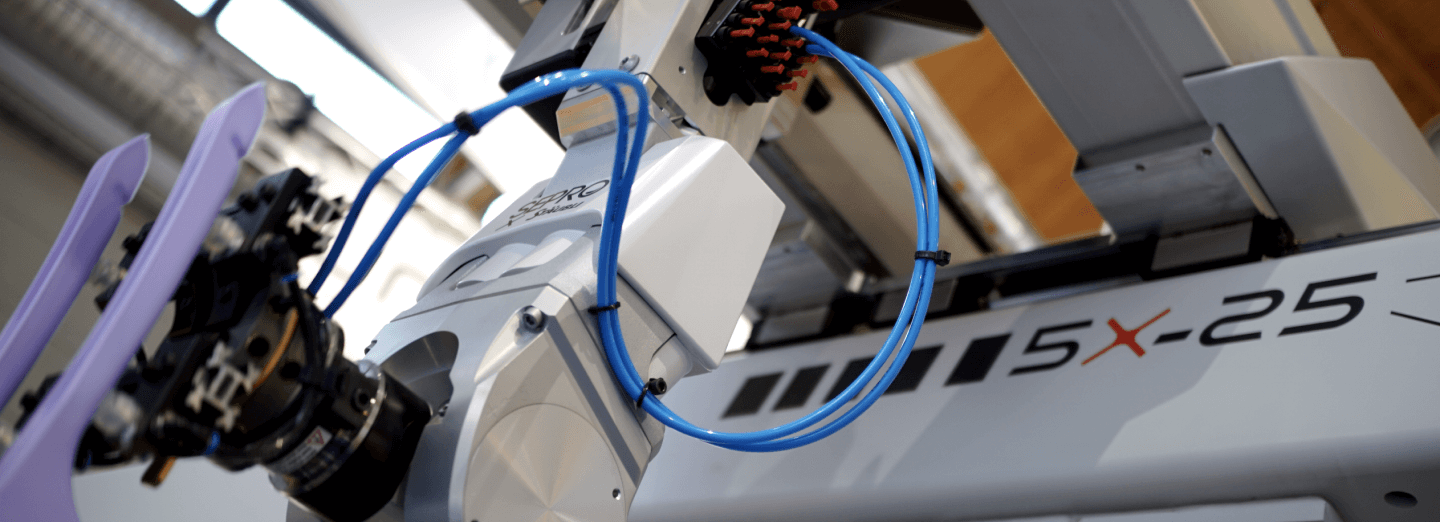

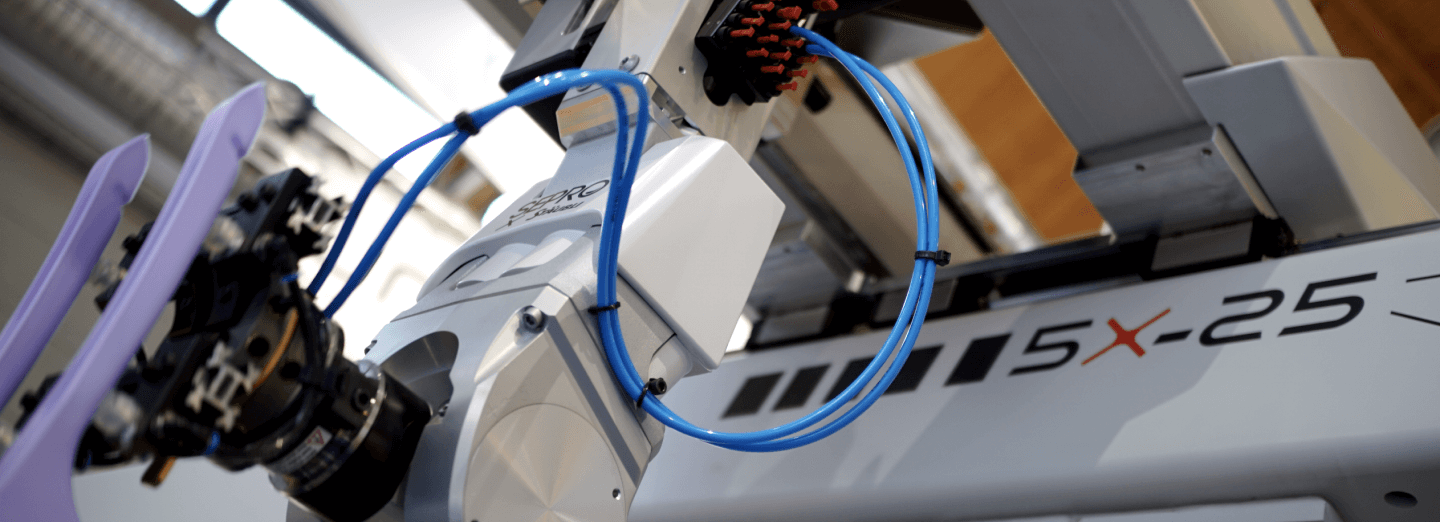

Visual 2

VISUAL

时长

4 days, of which 50 % practical work - Indicative duration

公开

校准员

方法技术员

维修技术员

要求的概念

None

Visual 2 / VISUAL / VISUAL 3控制器

Be able to analyse and program simple applications (part grip and release).

Be able to fix an electrical problem

Be able to carry out preventive maintenance.

Visual 2 / VISUAL

Be able to analyse and program simple applications (part grip and release). Be able to fix an electrical problem Be able to carry out preventive maintenance.

Visual 2 / Touch 2控制器 / VISUAL 3控制器

Programming and Troubleshooting course and a basic understanding of Programmable Logic Controllers and/or ladder logic.