Using a robot in production

Next sessions

On request

37 Waterside Barns, Lodge Farm Centre, Castlethorpe Business, Milton Keynes MK19 7ES

Know how to operate the robot. Be able to diagnose routine anomalies.

Hardware Safety Initialization procedures Movements in “manual mode” End Of Arm Tooling (EOAT): installing, checking

Choosing the program Home return and the first cycle End of production Changing the cycle's parameters in “auto” mode

Understanding the fault messages Troubleshooting and restarting after a fault

Cycle

Exploit

Control system

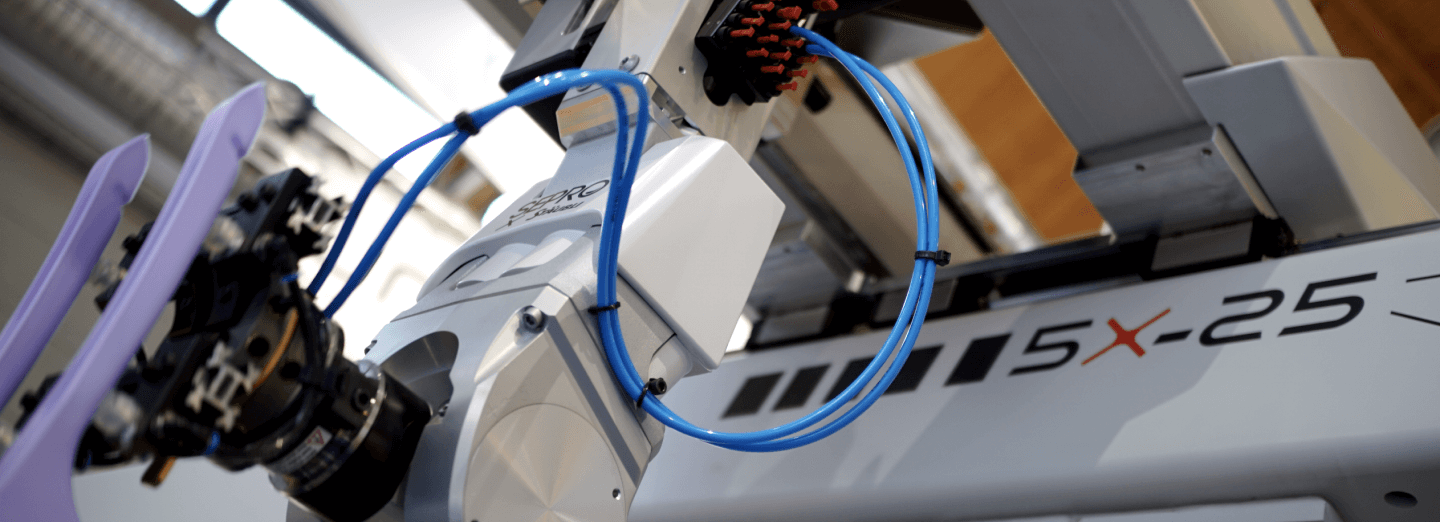

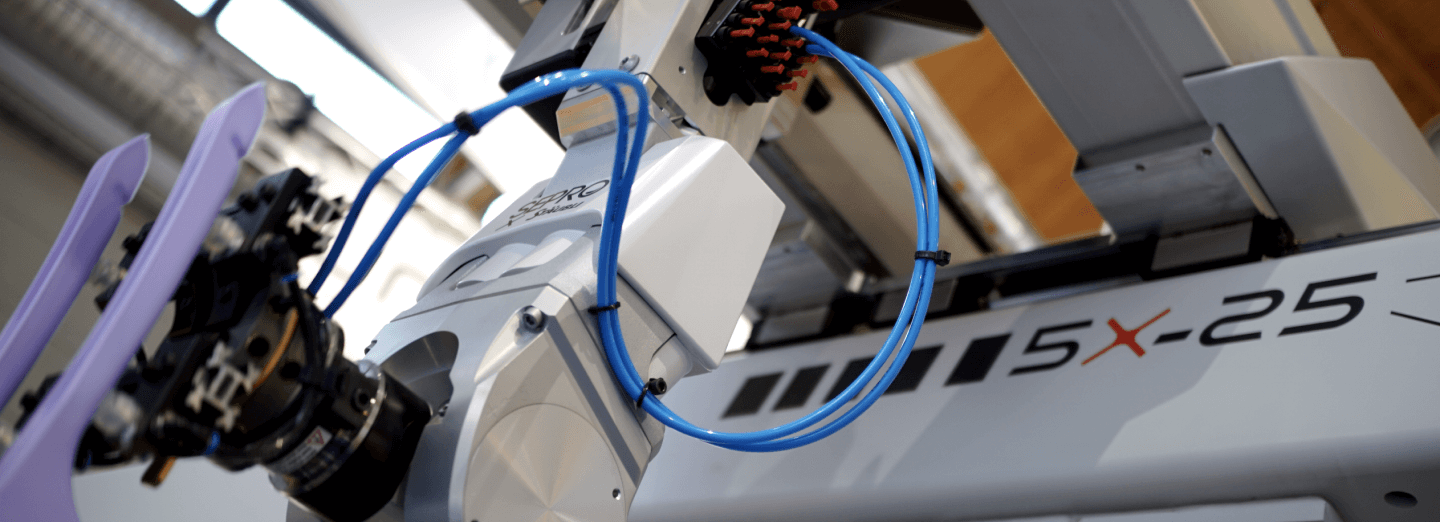

Visual 2

Visual 3

Length

1 whole day or 2 half days - Indicative duration

Audience

Operators

Adjusters

Prerequisites

None

Visual 2 / VISUAL / Visual 3

Know how to operate the robot.

Be able to diagnose routine anomalies.

Be able to create production cycles with Simple Pick & Place and EPS.

Visual 2 / Touch 2 / Visual 3

Provide instruction on the fundamentals of robot operation

Visual 2 / VISUAL / Visual 3 / 6X_VISUAL3

Know how to operate the robot.

Be able to diagnose routine anomalies.