Innovation in Automation Systems for injection molders is the theme for Sepro Group at Fakuma 2023

Sepro Group is bringing a total of 13 robots to the Fakuma 2023 trade fair as they demonstrate technical innovations that can help plastic injection molders increase productivity during challenging times. Sepro is exhibiting in Hall A1 on Stand 1203 at the plastics trade fair being held in Friedrichshafen, Germany, October 17 – 21. “Automation is the key to success for plastics injection-molders,” says Charles de Forges, CEO of Sepro Group. “The shortage of both skilled and unskilled labor, high energy and materials prices, environmental pressures, and uncertainty in the Asian manufacturing arena, are all major concern for molders. Fortunately, robotic automation offers at least a partial solution to each of these, by reducing dependence on manual labor, increasing efficiency, reducing waste, and reducing production costs. At Fakuma 2023, Sepro is presenting several innovations to demonstrate what’s possible through the intelligent application of automation.”

Download the press release (English)

Herunterladen der Presseinformation (Deutsch)

Télécharger le communiqué de presse (Français)

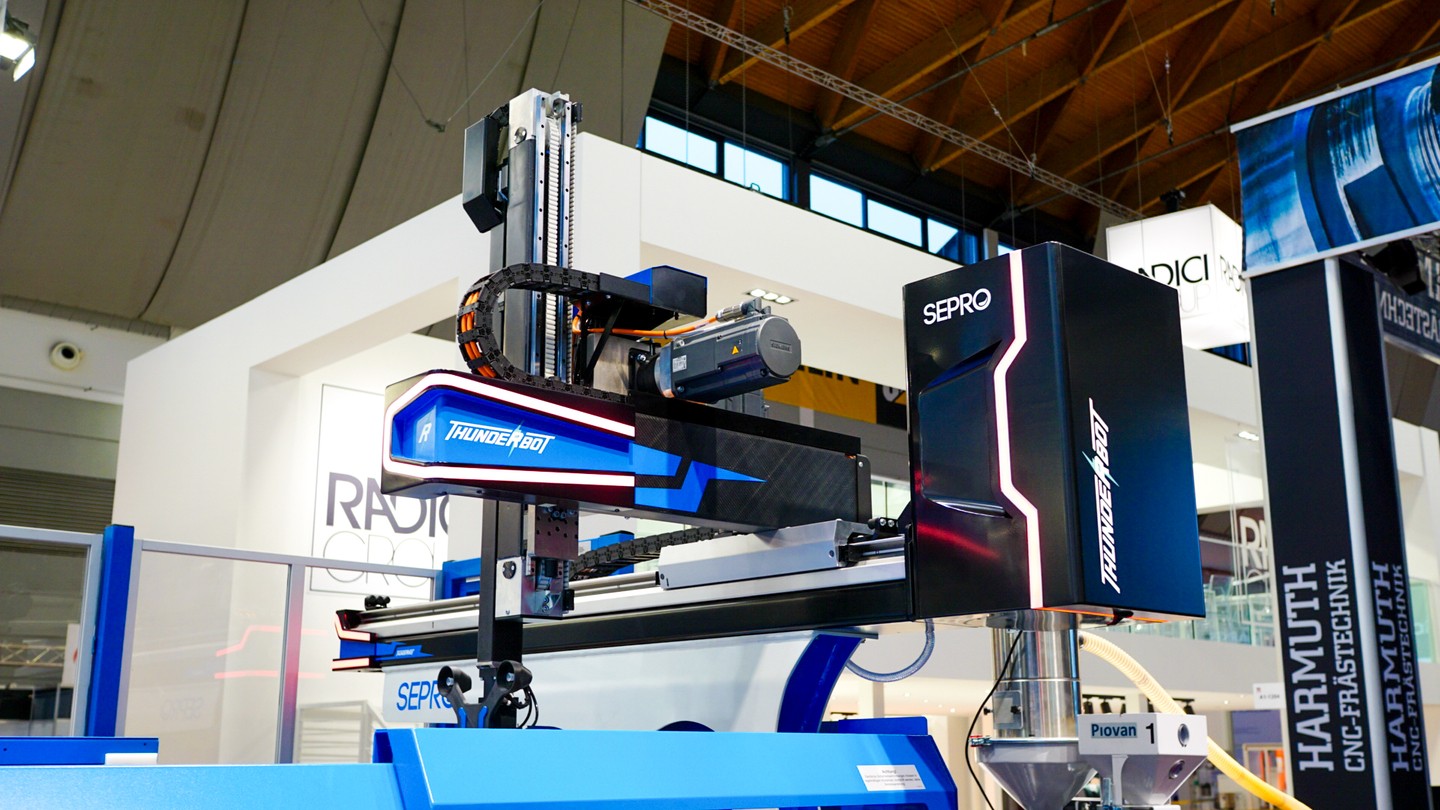

Sepro design innovations enable ‘ThundeRbot’ to reach highest speed

How would you redesign a general-purpose top-entry robot to make it as fast as possible? This was the challenge undertaken by engineers at Sepro Group, the French robot and injectionmolding automation supplier. The result of their efforts – the fastest top-entry robot Sepro has ever built -- can be seen in full-speed operation at Fakuma 2023, the plastics trade fair being held in Friedrichshafen, Germany, October 17 – 21. Sepro is exhibiting in Hall A1 on Stand 1203. Starting with a standard Success 11 8U robot, the designers made modifications that resulted in a robot that requires just a fraction of a second to remove a plastic part from an injection mold. At Fakuma, the ThundeRbot, as it has been named, can be seen operating on a Demag molding machine producing small cups. The overall cycle time is just 3.07 seconds and mold-open time – during which the robot arm enters the mold, removes the part, and exits again – is a mere 0.79 seconds. “We challenged our design team to implement every possible measure in order to increase speed,” explains Charles de Forge, CEO, Sepro Group. “So, what we are showing is a concept machine and, just as automakers use concept cars to introduce innovative new ideas, the ThundeRbot is Sepro’s attempt to demonstrate how our engineers innovate – think outside the box, if you will – to overcome challenges to achieve a specific objective.”

Download the press release (English)

Herunterladen der Presseinformation (Deutsch)

Télécharger le communiqué de presse (Français)

Sepro Connect Dashboard helps molders optimize operation of automated cells plantwide

Seamlessly gathering data from all the equipment in automated plastic injection-molding cells – including the molding machines – the new Sepro Connect automation cell dashboard from Sepro Group promises to transform the way plastics-product manufacturers manage production, enhance overall productivity and control energy consumption. The concept for the Sepro Connect dashboard was first seen at K 2022, where it gathered data from a single highly automated molding cell on the Sepro stand. Now, at the Fakuma 2023 trade fair (Messe Friedrichshafen, 17 to 21 October), Sepro engineers will demonstrate an expanded range of capabilities. These include the ability to gather and present information from multiple plastic molding cells in different locations. At Fakuma, the system will monitor equipment not only on the Sepro stand, but it will also gather data from robots running in the booths occupied by many IMM partner companies. The enhanced system also now can monitor energy consumption, helping businesses reduce their environmental footprint and operational costs.

Download the press release (English)

Herunterladen der Presseinformation (Deutsch)

Télécharger le communiqué de presse (Français)