Discover the Three Unique Cells in Sepro’s Booth at NPE 2024

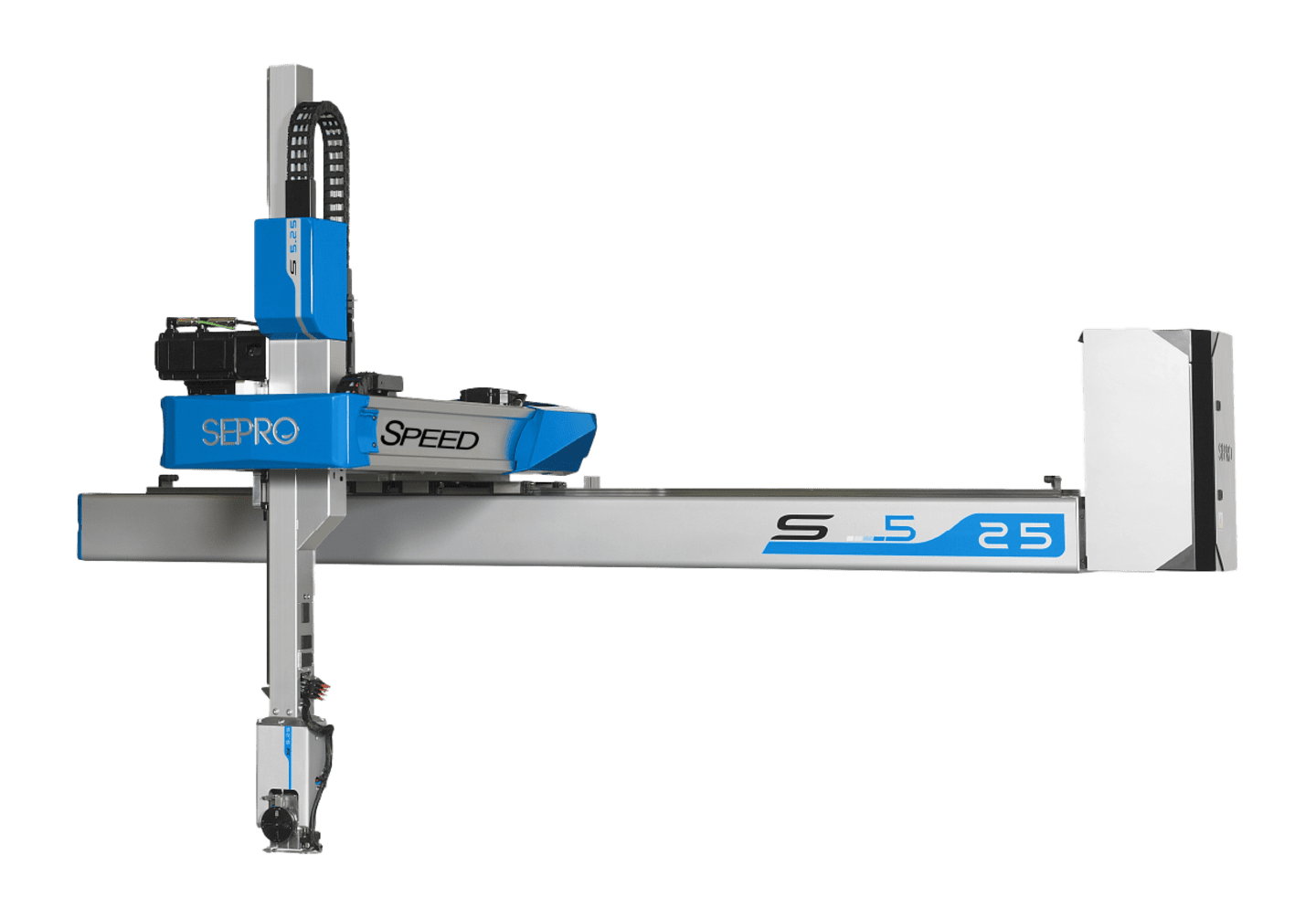

Sepro Speed and Agility Comparison Cell

In this cell, our S5-25 Speed robot is paired with our 5X-25 robot to compare performance in side-by-side tests of speed and agility. Both units are based on the same mechanical platform but, while the S5-25 Speed is built for fast acceleration and a short cycle time, the 5X-25 is a 5-axis-servo configuration with a 2-axis-servo wrist, enabling it to excel at complex and precision part manipulation.

Take a look at this cell, where each robot will demonstrate it’s unique skills, and talk to a Sepro expert to determine which model robot will best fit the needs of your operation.

Automation by Sepro Cell

This is the first NPE in which Sepro has shown a molding machine in our booth, and it’s worth checking out the automation that we have supporting this injection molding operation. Our automation cell features three robots operating in support of a 125-ton Q Series injection-molding machine from Milacron. A Success 11X 5-axis Cartesian robot, a 6-axis 6X-170 articulated-arm unit, and a cobot handle not only part removal but also degating, laser marking, sorting (using 2D & 3D vision), label application and packing. All operations are integrated by our Visual 3 control system.

“The more you can do in and around the molding machine to increase efficiency and add value to the products you mold, the greater your competitive advantage,” says Jim Healy, VP Sales & Marketing for Sepro. “In this one demonstration, we’re showing how three different kinds of robots, fully integrated with the molding machine, can perform operations that otherwise would have required multiple operators. Higher-quality work is being done faster and more safely while using much less floor space.”

Sepro Goes Big

Sepro has always been the leader in large-part automation; and you’ll get a sense of that at NPE224 when you stop by the Sepro booth and see the largest robot at the show. Our 7X-55 robot is designed to serve injection-molding machines as large as 2500 tons. This cell highlights the impressive capabilities of our large robot lines, demonstrating the handling of four different large parts: a roll-out garbage can, a large-diameter pipe fitting, an automotive component and a heavy dumbbell. Quick-change end-of-arm tooling allows the robot to handle each part in succession, demonstrating how automation can support efficient short-run production of large components.

“Sepro has always been well-known for making big robots,” explains Jim Healy, VP Sales & Marketing. “Molders serving the automotive industry, and others that require machines with 5000 tons or more of clamp force, have come to us for decades. But despite the size of the parts involved, these applications are not much different from any other. The efficiency and productivity benefits of automation can only be realized using robots that are not only big and strong, but also fast, precise, and flexible.”