Programming complex production cycles

Be able to develop and fine-tune complex production

Programming principles

Basic instructions

IMM / Robot interface

CNC’s capacities

Optimising production cycles

Program management

Program on the PC

Wordings *

Studying real applications

advanced programming

Condition test

Internals bits

Counters

Standard PLC

Regular stacking sequences

Managing restarts

Studying real applications

StUDYING COMPLEX CYCLES *

Stacking / unstacking type stacking sequences

Stacking on cooling table (FIFO)

Stacking with spacers

General stacking sequences

Cycles with insert placing

Studying real applications

*Depending on the trainee’s needs

All of our courses are based on alternating between the transfer of know-how and good practice, with concrete exercises and real-life situations. All trainees will be given a folder containing the documents, exercises and corrections of the practical work done during the course.

Trainees are assessed by the trainer for each module to measure the knowledge acquired at each step of the course, through practical works.

Zyklus

Programmierung

Kontrolle und Steuerung

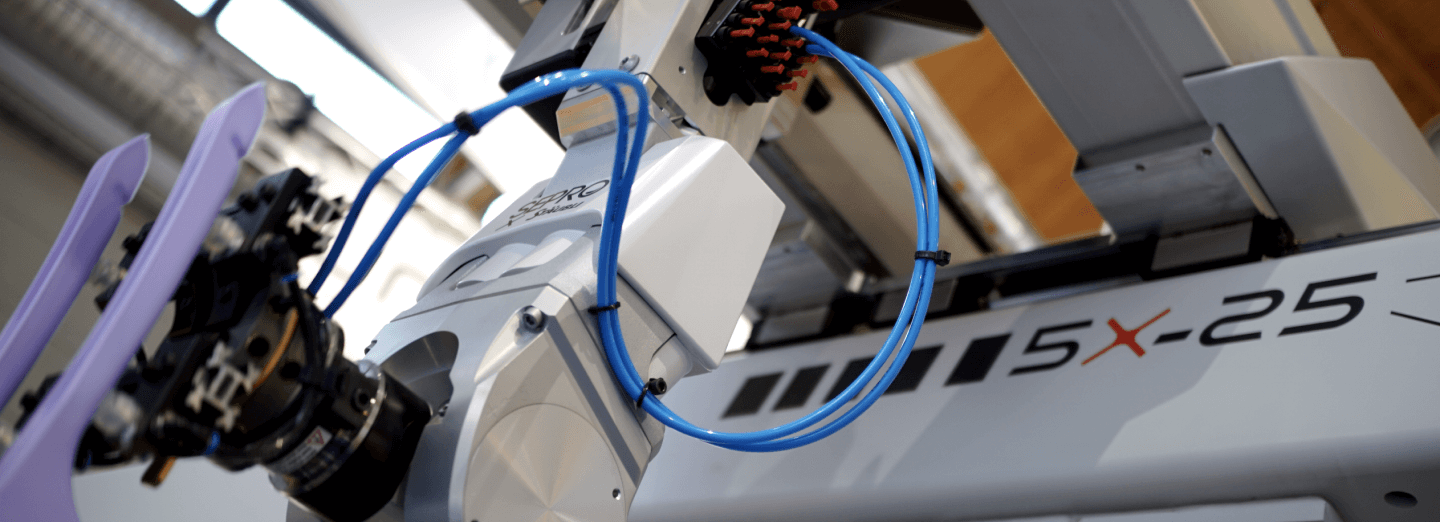

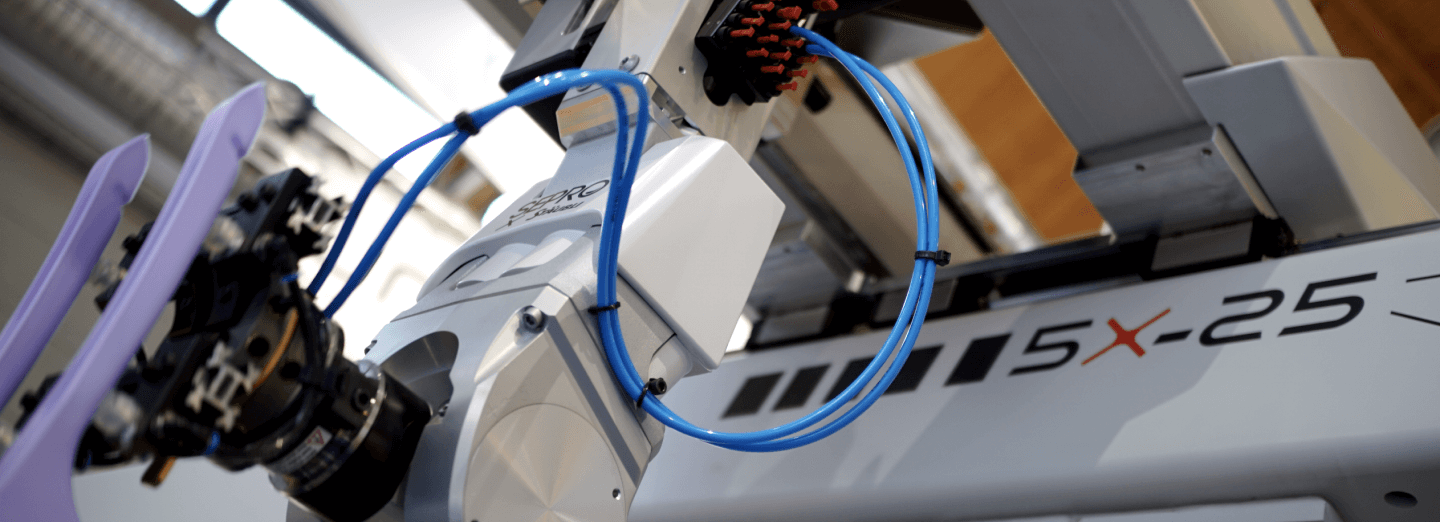

Visual 2

VISUAL

Visual 3

Dauer

3,5 days

Öffentlich

Einrichter

Verfahrenstechniker

Wartungstechniker

Verlangte Kenntnisse

Be able to write a simple part grip and release program.

Personenanzahl

3 to 6 persons maximum

Zugangsmodalitäten

The required knowledge will be validated on the results of the assessment questionnaires.

Formalisierung am Ende der Schulung

Attendance sheet provided by Sepro

Visual 3

Analazing and programming of simple applications

Visual 2 / VISUAL / Visual 3

Be able to develop and fine-tune complex production

Visual 2 / VISUAL

Be able to analyse and program simple applications (part grip and release). Be able to fix an electrical problem Be able to carry out preventive maintenance.