Progamming and optimizing production cycles

Be able to analyse and program simple applications (part grip and release)

Be able to optimise a program

PRINCIPLE OF THE NUMERIC CONTROL SYSTEM

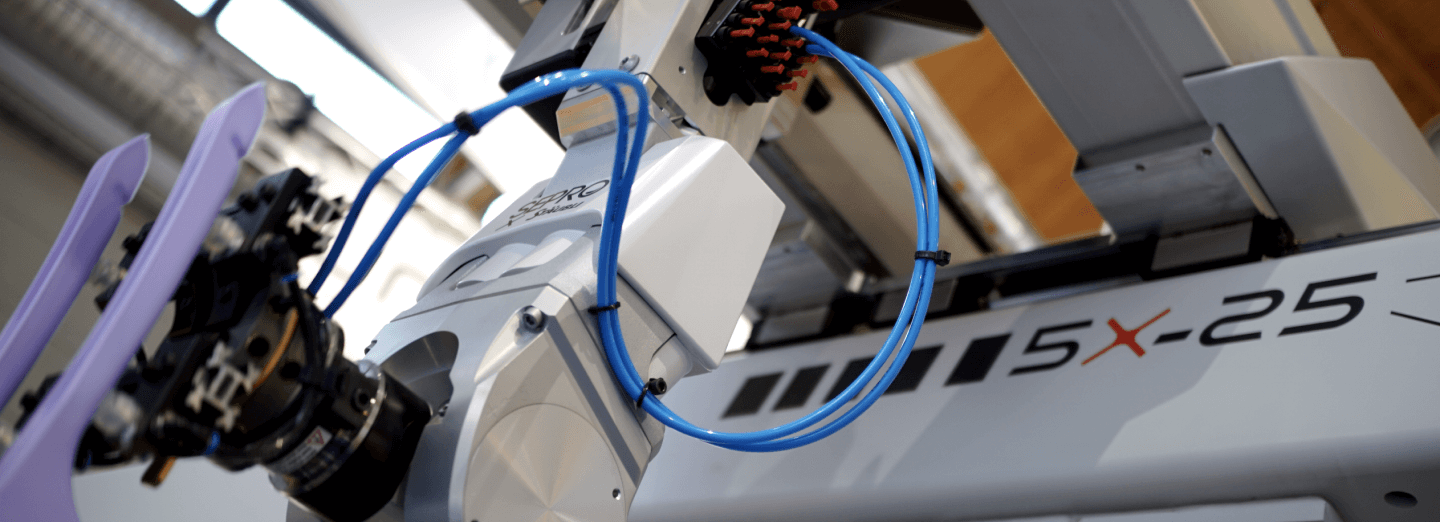

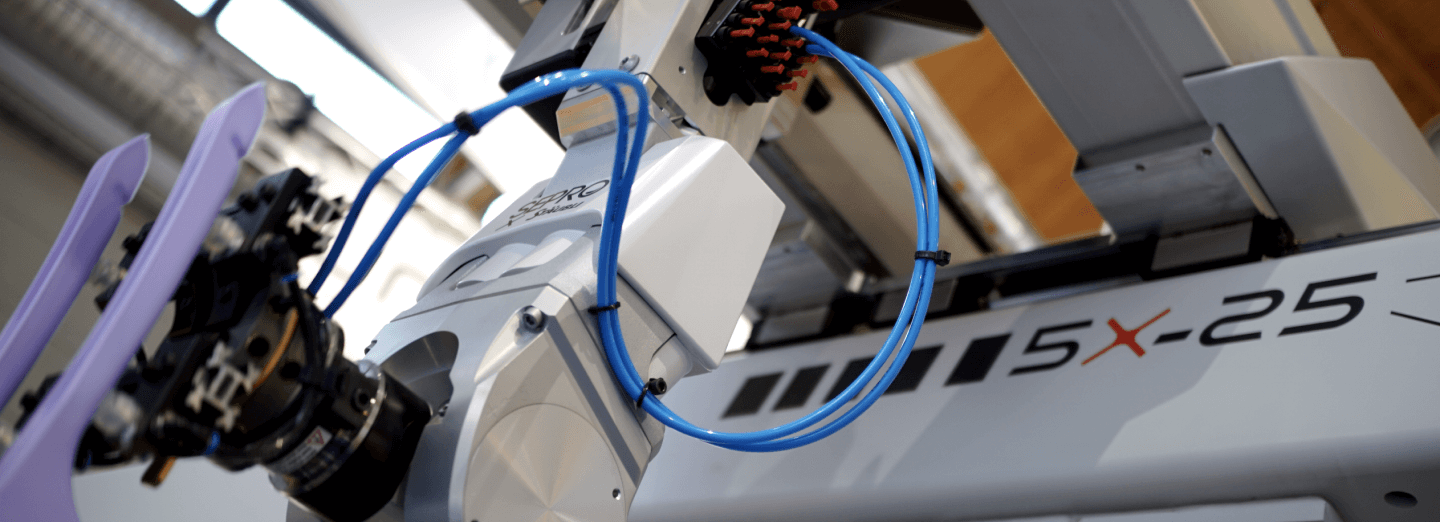

Hardware

Safety

Procedures for starting production

Production: start - stop

CREATING CYCLES

The Simple Pick & Place module

Creating cycle with Simple Pick & Place

The cycle parameters

PROGRAMMING

Program structure

Basic instructions

Writing and testing a simple program with cycle parameters

IMM / Robot interface

Creating and testing a program with interface

OPTIMIZING PRODUCTION CYCLES

Extended programming of the numeric axes and cycle options

Numeric control system’s capacities

Creating and testing an optimized program

Memory management

Creating EPS sources

The condition test

STUDYING THE FUNCTIONS

Programming on PC

Simple palletising

The cycle counters

Studying real applications

All of our courses are based on alternating between the transfer of know-how and good practice, with concrete exercises and real-life situations. All trainees will be given a folder containing the documents, exercises and corrections of the practical work done during the course.

Trainees are assessed by the trainer for each module to measure the knowledge acquired at each step of the course, through practical works.

Zyklus

Programmierung

Kontrolle und Steuerung

Visual 2

VISUAL

Touch 2

Visual 3

6X_VISUAL3

TOUCH

Dauer

4 days

Öffentlich

Einrichter

Verfahrenstechniker

Wartungstechniker

Verlangte Kenntnisse

None

Personenanzahl

3 to 8 people max

Zugangsmodalitäten

Open to everybody

Formalisierung am Ende der Schulung

Attendance sheet provided by Sepro

Visual 2 / VISUAL

Be able to use the robots’ most advanced functions.

Visual 2 / VISUAL

Be able to analyse and program simple applications (part grip and release). Be able to optimise a program.

Visual 2 / VISUAL / Visual 3

Be able to develop and fine-tune complex production