Creating production cycles

Nächste Sitzungen

On request

31, Rue Jean Esswein 85000 La Roche Sur Yon FRANCE

On request

235, rue de la Prairie Parc Industriel Sud 01100 Groissiat FRANCE

Know how to operate the robot.

Be able to diagnose routine anomalies.

Be able to create production cycles with Simple Pick & Place and EPS.

PRINCIPLES OF THE ROBOT AND THE CONTROL SYSTEM

Hardware

Safety

Initialization procedures

Movements in manual mode

End Of Arm Tooling (EOAT): installing, checking

STARTING PRODUCTION

Choosing the program

Home return and the first cycle

End of production

Changing the cycle’s parameters in auto mode

CREATING CYCLES

The Simple Pick & Place module

Creating cycles with Pick & Place

The cycle parameters

EPS principles

Analyzing a production cycle

Procedure for creating cycles with EPS

Modifying parameters

TROUBLESHOOTING

Understanding the fault messages

Troubleshooting and researching after a fault

All of our courses are based on alternating between the transfer of know-how and good practice, with concrete exercises and real-life situations.

All trainees will be given a folder containing the documents, exercises and corrections of the practical work done during the course.

Trainees are assessed by the trainer for each module to measure the knowledge acquired at each step of the course, through practical work.

Zyklus

Betrieb

Kontrolle und Steuerung

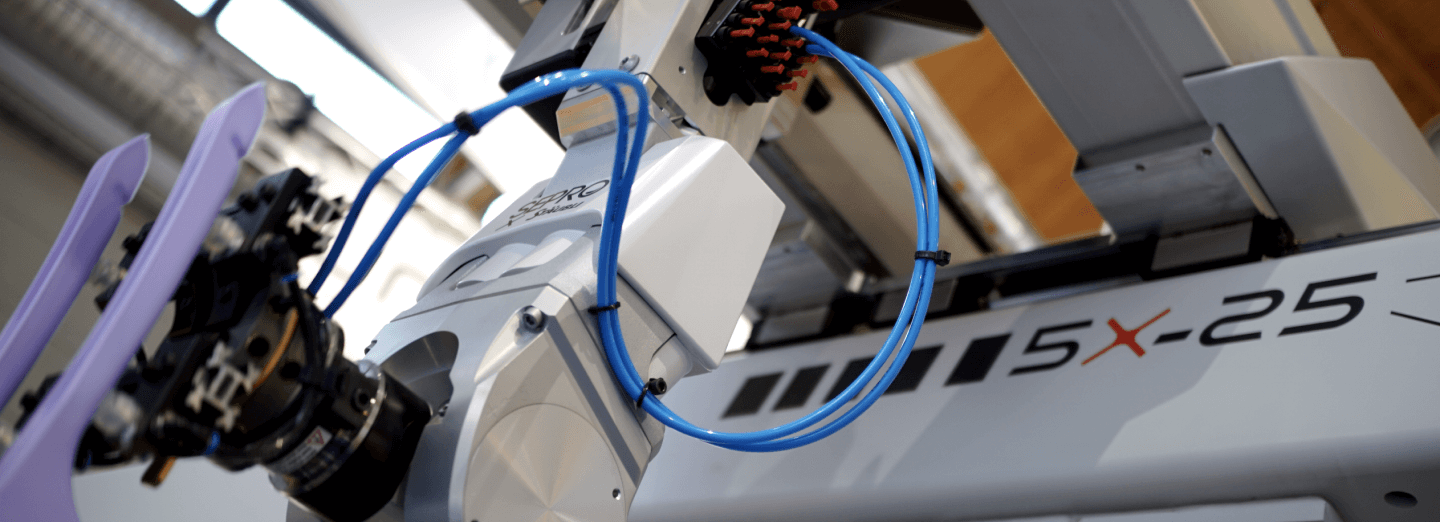

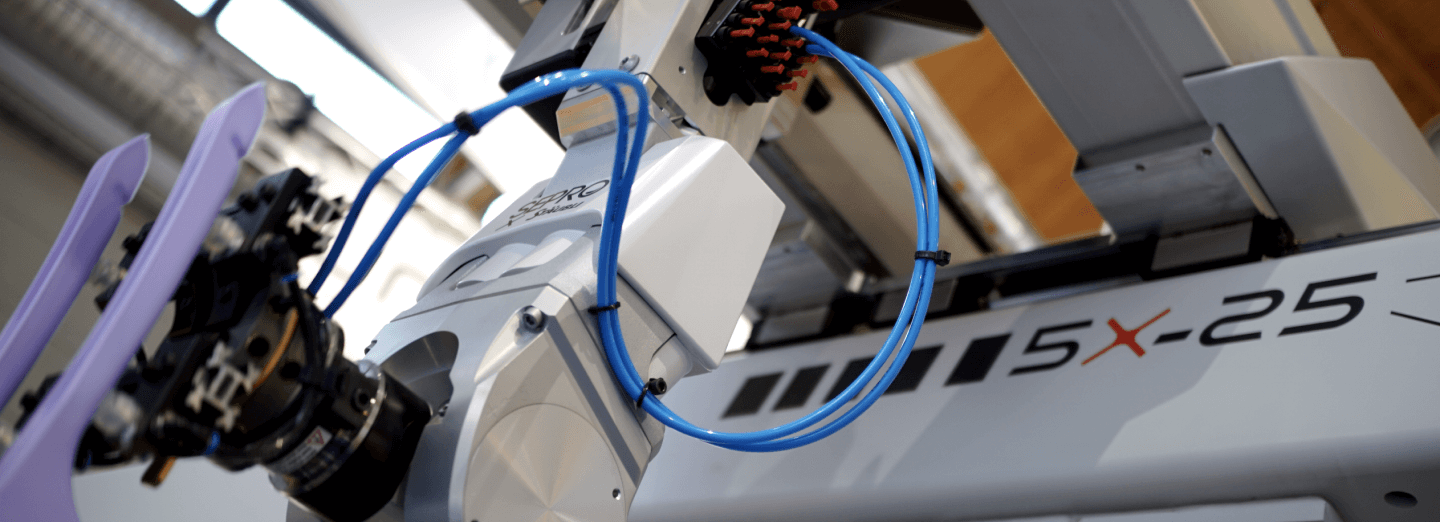

Visual 2

VISUAL

Visual 3

Dauer

1.5 day / 10.5 hours

Öffentlich

Bediener

Einrichter

Verlangte Kenntnisse

None.

Personenanzahl

3 to 8 persons maximum

Zugangsmodalitäten

Open to everybody

Formalisierung am Ende der Schulung

Attendance sheet provided by SEPRO

Visual 2 / Visual 3

Know how to operate the robot. Be able to diagnose routine anomalies.

Visual 2 / VISUAL / Visual 3

Know how to operate the robot.

Be able to diagnose routine anomalies.

Be able to create production cycles with Simple Pick & Place and EPS.

Visual 2 / Touch 2 / Visual 3

Provide instruction on the fundamentals of robot operation