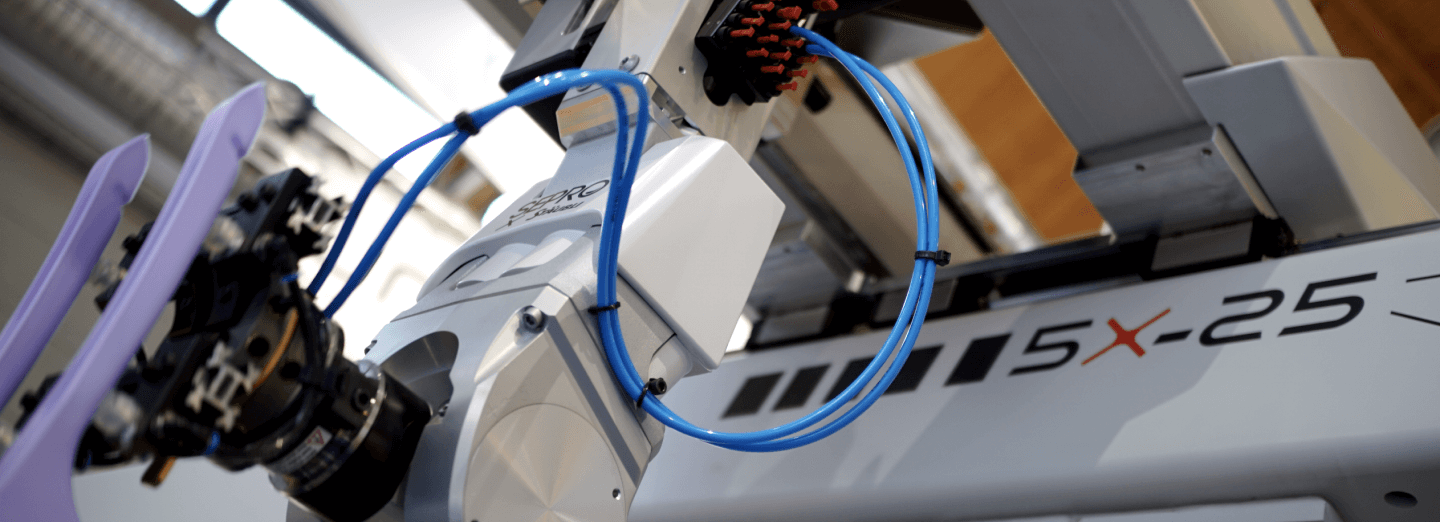

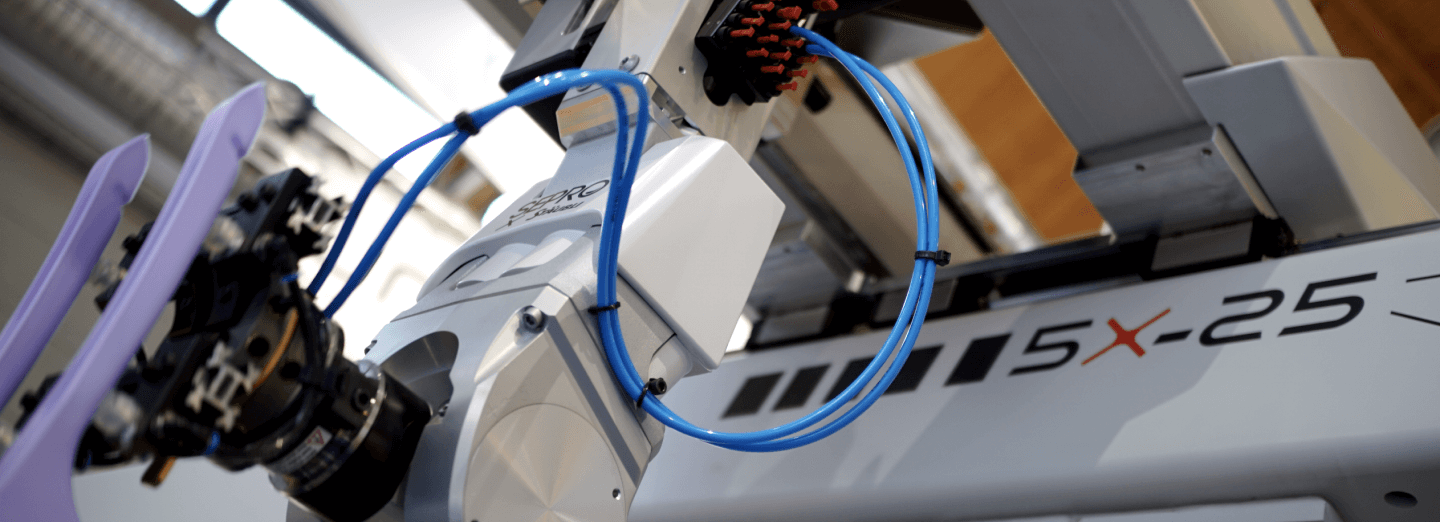

Robot programming and maintenance

Prochaines sessions

On request

37 Waterside Barns, Lodge Farm Centre, Castlethorpe Business, Milton Keynes MK19 7ES

Be able to analyse and program simple applications (part grip and release). Be able to fix an electrical problem Be able to carry out preventive maintenance.

Hardware Safety Procedures for starting production Production: start - stop

The Simple Pick & Place module Creating cycles with Simple Pick & Place The cycle parameters EPS principles Analysing a production cycle Procedures for creating cycles with EPS

Program structure Basic instructions Creating an EPS cycle and changing the program IMM / Robot interface Creating and testing a program with interface

The cabinet components The electric drawings Power output Emergency stop line Inputs/Outputs The numeric axes The pneumatic diagram Repairing failures

Understanding the fault messages The signalling Leds

The general parameters Calibrating the numeric axes

Pneumatic Mechanic Electric

Cycle

Exploiter

Maintenir

Programmer

Contrôle commande

Visual 2

VISUAL

Durée

4 days, of which 50% practical work - Indicative duration

Public

Techniciens Méthodes

Techniciens Maintenance

Notions requises

To be allowed to intervene in an electrical cupboard under high pressure.

Visual 2 / VISUAL / Visual 3

Be able to analyse and program simple applications (part grip and release).

Be able to fix an electrical problem

Be able to carry out preventive maintenance.

Visual 2 / VISUAL

Be able to use the robots’ most advanced functions.

Visual 2 / TOUCH 2 / Visual 3

Covers robot operation, programming, robot and controller cabinet hardware, troubleshooting simple fault and periodic maintenance.