Robot programming and maintenance

Próximas sessões

On request

31, Rue Jean Esswein 85000 La Roche Sur Yon FRANCE

On request

235, rue de la Prairie Parc Industriel Sud 01100 Groissiat FRANCE

Be able to analyse and program simple applications (part grip and release).

Be able to fix an electrical problem

Be able to carry out preventive maintenance.

PRINCIPLES OF THE NUMERIC CONTROL SYSTEM

Hardware

Safety

Procedures for starting production

Production: star - stop

CREATING CYCLES

The Simple Pick & Place module

Creating cycles with Simple Pick & Place

The cycle parameters

PROGRAMMING

Program structure

Basic instructions

IMM / Robot interface

Creating and testing a program with interface

TROUBLESHOOTING PROCEDURE

HARDWARE ARCHITECTURE

The pneumatic movements

CAN bus

The work zones

The numeric movements

The peripherals

The pendant

Safety

IMM / Robot interface

Inputs / Outputs

Repairing failures

THE MACHINE CONFIGURATION

The general parameters

Calibrating the numeric axes

PREVENTIVE MAINTENANCE

Pneumatic

Mechanic

Electric

All of our courses are based on alternating between the transfer of know-how and good practice, with concrete exercises and real-life situations. All trainees will be given a folder containing the documents, exercises and corrections of the practical work done during the course.

Trainees are assessed by the trainer for each module to measure the knowledge acquired at each step of the course, through practical works

Ciclo

Manter

Programar

Controle comando

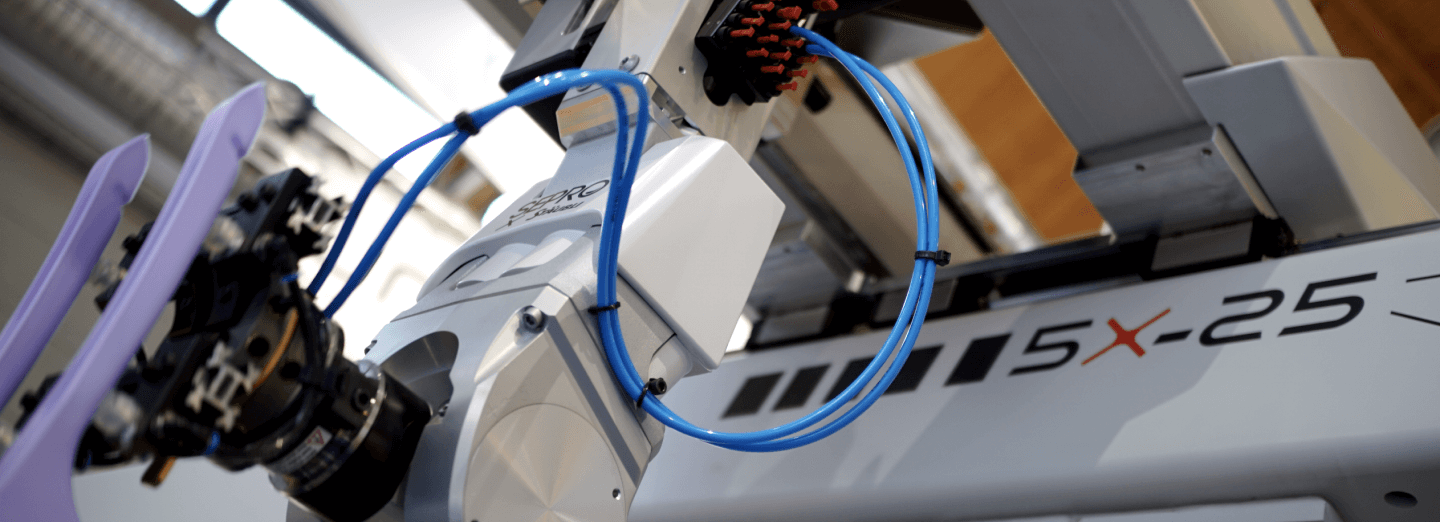

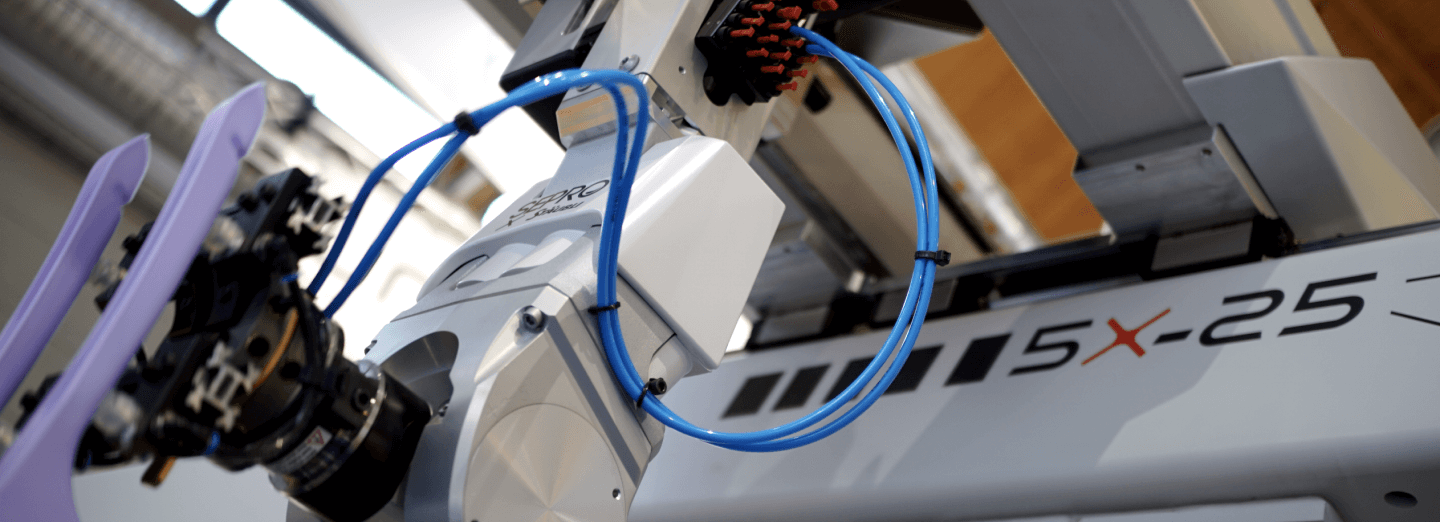

Visual 2

VISUAL

Visual 3

Duração

4 days / 28H

Público

Técnicos de Métodos

Técnicos de Manutenção

Noções requeridas

Be allowed to intervene in an electrical cabinet under voltage

Número de pessoas

3 to 6 persons max

Modalidades de acesso

A copy of the electrical accreditation certificate must be provided before the start of the training course.

Formalização no fim da formação

Attendance sheet provided by Sepro

Visual 2 / Touch 2 / Visual 3

Covers robot operation, programming, robot and controller cabinet hardware, troubleshooting simple fault and periodic maintenance.

Visual 3

Analazing and programming of simple applications

Visual 2 / VISUAL

Be able to use the robots’ most advanced functions.